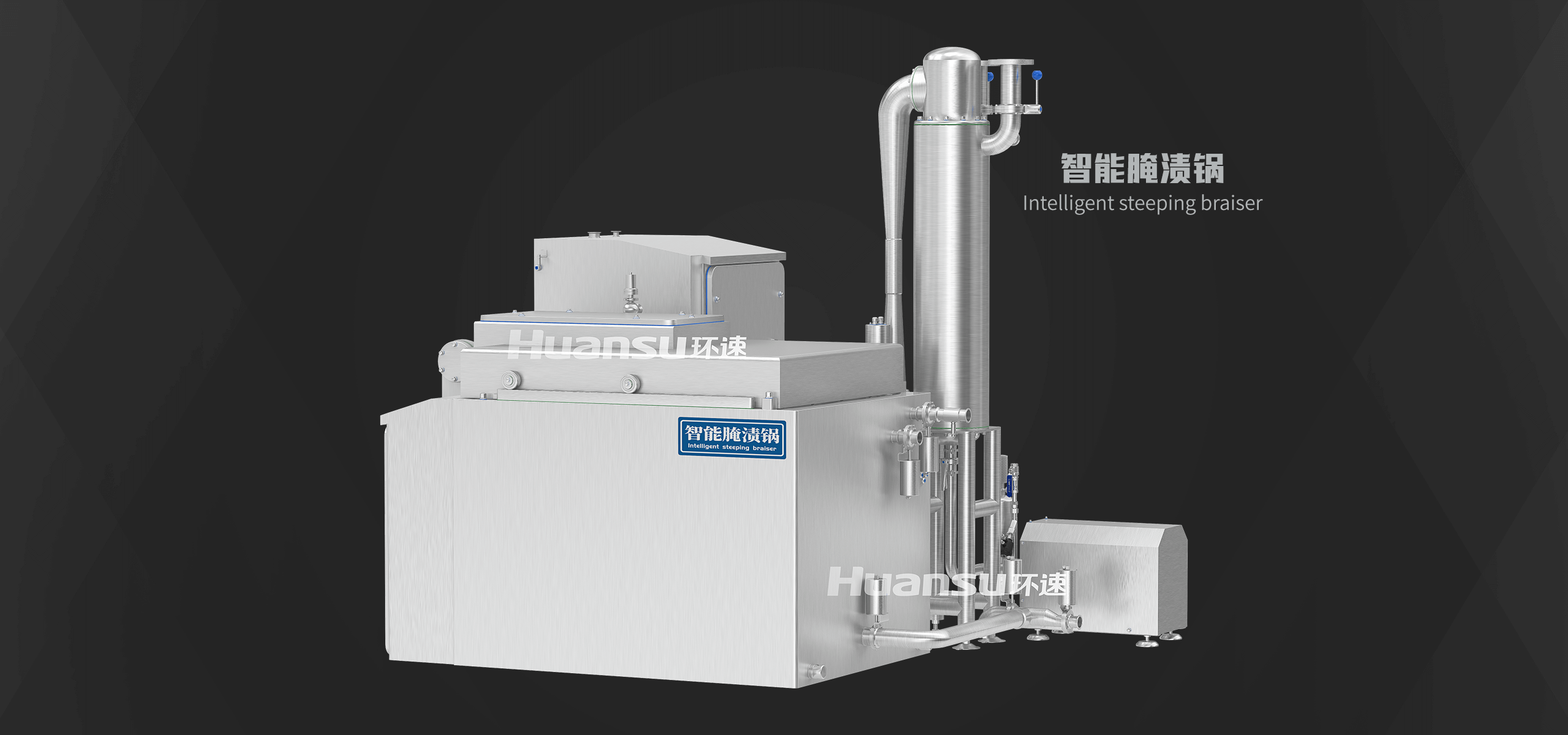

Product Use

This equipment is used for vacuum pickling processing of large quantities of pickled foodstuffs (candied fruit, pickles, marinated meat, bean products, etc.).

Applicable Customers

This equipment is suitable for leisure food processing plant, sauce and brine processing plant, cooked food processing plant, canned food processing plant, central kitchen, pre-prepared vegetable processing plant, fresh food factory and other enterprises.

R&D Background

The traditional marination process is slow, and there are problems such as insufficient and uneven marination and big difference in food taste, which is difficult to adapt to the new situation of large-scale and standardized commodity production. This equipment applies the principle of vacuum impregnation, greatly accelerates the penetration process of sugar, salt and other flavoring substances, and realizes the breakthrough improvement of the impregnation efficiency; the equipment adopts the intelligent pressure control and temperature control technology, and accurately controls the technical details of the impregnation process, and realizes the standardized production.

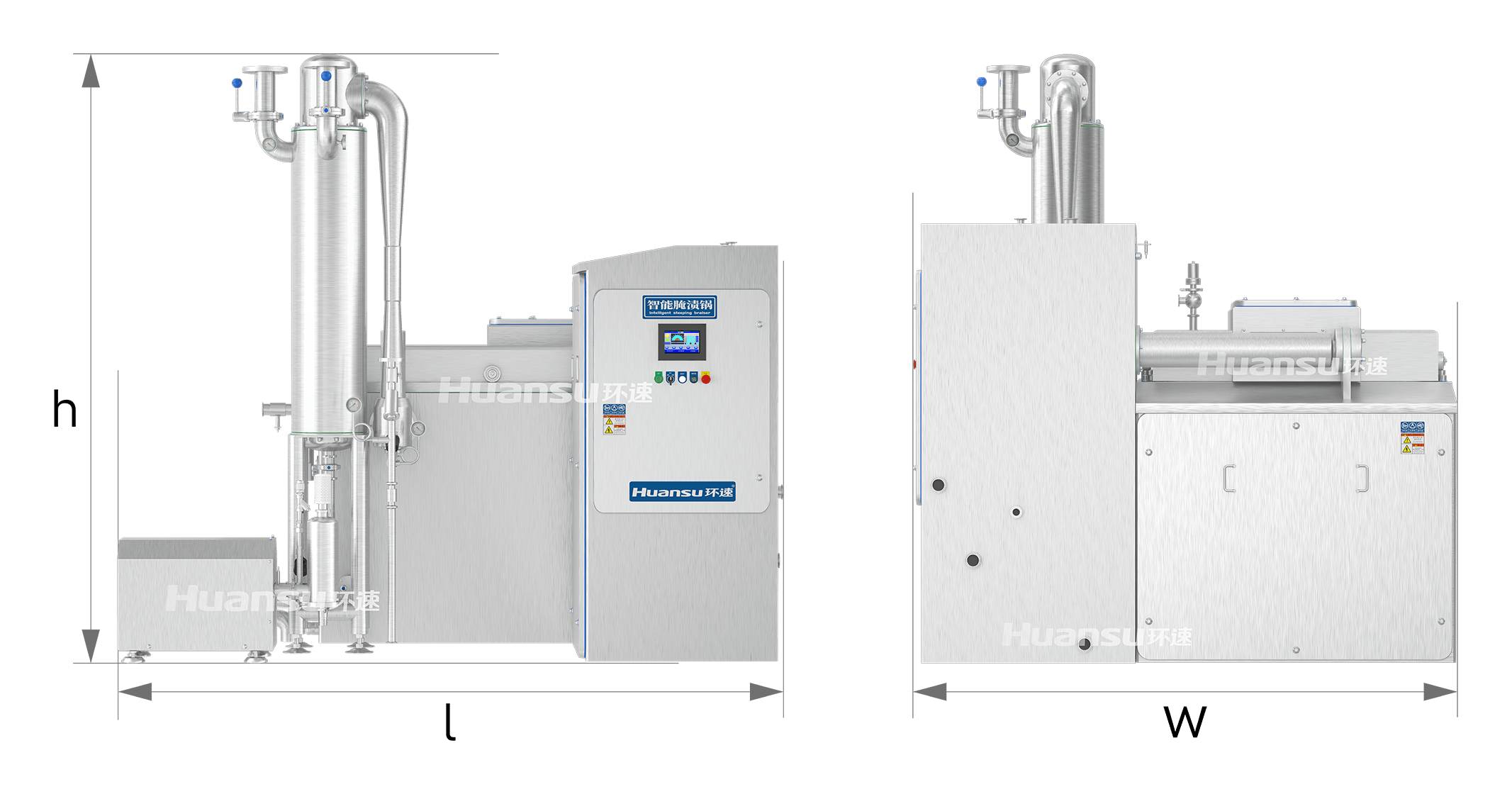

技術(shù)參數

| 項目 | 單位 | XTYG09 | ||

|---|---|---|---|---|

| 設備本體 | 鍋體最大容積 | L | 1400 | |

| 鍋體有效容積 | L | 1200 | ||

| 最大加熱溫度 | ℃ | 100 | ||

| 每鍋醬鹵數量 | 盤(pán) | 21 | ||

| 衛生等級 | — | 醫藥級 | ||

| 托盤(pán)尺寸(W×D×H) | mm | 900×450×110 | ||

| 最大外形尺寸(W×D×H) | mm | 2821×2295×3006(開(kāi)蓋狀態(tài)) | ||

| 鍋體工作尺寸(W×D×H) | mm | 1400×1070×1022 | ||

| 加熱形式 | — | 蒸汽加熱 | ||

| 冷卻形式 | — | 冷水/抽真空 | ||

| 保溫形式 | — | 鍋體加熱夾層保溫 | ||

| 接口尺寸 | 蒸汽入口 | — | φ51卡箍接頭 | |

| 疏水排水口 | — | φ51卡箍接頭 | ||

| 排湯口 | — | φ76卡箍接頭 | ||

| 進(jìn)湯口 | — | φ51卡箍接頭 | ||

| CIP進(jìn)出口 | — | φ51卡箍接頭 | ||

| 真空泵排水口 | — | φ51卡箍接頭 | ||

| 真空泵排氣口 | — | φ51卡箍接頭 | ||

| 真空泵進(jìn)水口 | — | φ27卡箍接頭 | ||

| 射流器蒸汽進(jìn)口 | — | φ27卡箍接頭 | ||

| 換熱器冷卻水循環(huán)接口 | — | DN50法蘭 | ||

| 冷水循環(huán)口 | — | φ51卡箍接頭 | ||

| 外圍供給 | 蒸汽壓力 | Mpa | 0.3 | |

| 壓縮空氣壓力 | Mpa | 0.6 | ||

| 電源電壓(三相五線(xiàn)制) | — | 380V 50Hz | ||

| 電源功率 | Kw | 8.5 | ||

customization

We provide non-standard customisation services, can be based on the standard machine to modify the specifications or add new functions, and provide equipment in the process chain upstream and downstream of the equipment, including cleaning, cooking, food cooling, container cleaning and other processing equipment, for you to create a multi-functional production of digital intelligence workshop.